Machining

Za a iya ƙara wasu zeolites na wucin gadi a cikin polymer, kuma ƙwayar aluminosilicate na iya ɗaukar ƙamshi na musamman a cikin kayan.Ta hanyar adadi mai yawa na cavities crystal a cikin foda, adsorbent zai iya kama kananan kwayoyin halitta masu samar da wari.An yi nasarar amfani da adsorbents na kama ƙwayoyin ƙwayoyin cuta zuwa bututun extrusion na polyolefin, allura da tasoshin gyare-gyaren extrusion, kayan marufi, marufi da kayan rufewa.Hakanan za'a iya ƙara foda na kwayoyin halitta a cikin filastik a matsayin mai cire humidifier don cire danshi a ciki.

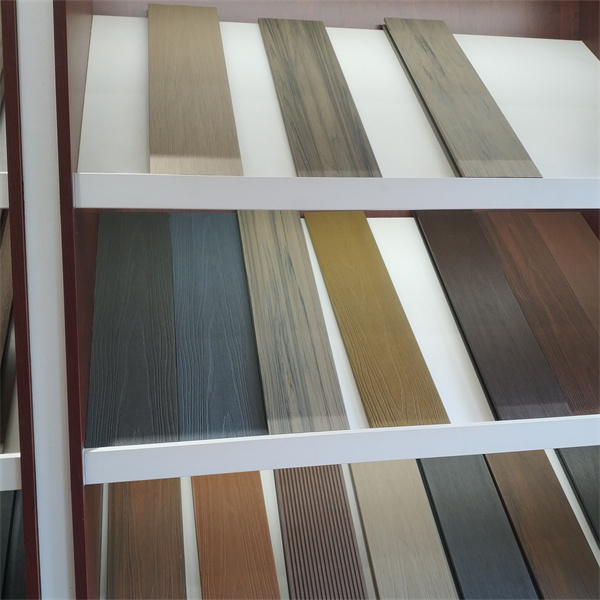

1. Co extruded filastik itace dabe ne haske a inganci da nauyi fiye da filastik itace dabe.Kamar kayan filastik da kayan itace, ingantaccen aiki yana da inganci sosai a cikin dukkan tsarin sufuri, musamman a cikin alluna masu ƙarfi.Dole ne ku yi aiki tare a cikin 2.3.Itacen filastik da aka haɗa ya fi sauƙi, wanda ba wai kawai yana rage ƙarfin ƙarfin aiki na ma'aikata ba, har ma yana ceton farashin aiki yadda ya kamata.Bugu da ƙari, nauyin gine-ginen injiniya kamar ganuwar kuma ana samun sauƙin sauƙi.

2. Sautin launi kuma ya fi kyau.Ingantattun kayan katako na filastik za su shuɗe kaɗan kuma da yawa a cikin shekaru 2-3 bayan shigarwa, kuma za a sami kurakurai a cikin sautin farko, wanda kuma yana ba wa yawancin al'umma ciwon kai.Co extruded filastik itace yana tabbatar da wannan.Kauri na launi na kariyar launi a saman yana ƙara lokacin riƙe launi zuwa kimanin shekaru 10.

3. Farashin daidai yake da na katako na katako na filastik.Kafin binciken samfur da haɓakar katako da shimfidar bene na filastik, an tsara farashin albarkatun ƙasa da auna.Ba wai kawai ya wajaba don ƙetare halaye na katako na katako na filastik ba, amma har ma don sarrafa farashin sayan a farashin daidai da katako na katako.

A cikin kalma, shimfidar bene na katako na haɗin gwiwa ya shahara sosai a yanzu.Yana da ba kawai muhalli m, amma kuma m.Ana iya amfani da shi na dogon lokaci a ƙarƙashin yanayin yanayi daban-daban ba tare da matsalolin inganci ba